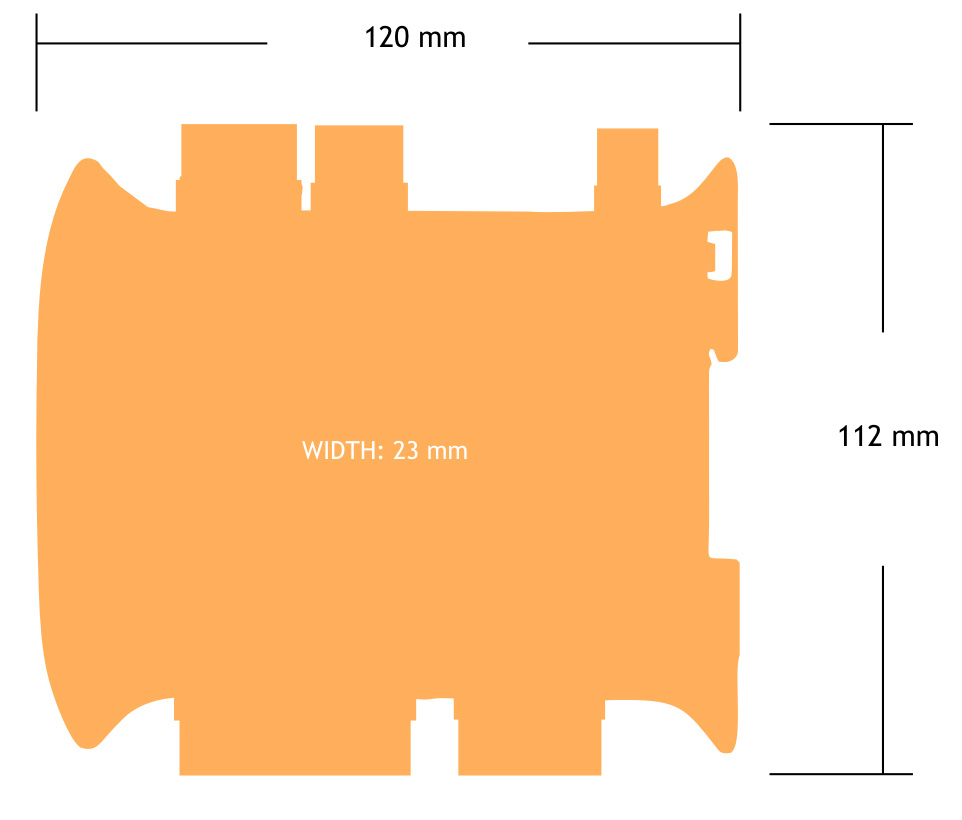

LCD20 | Load Cell DIN Rail Signal Amplifier

- Intelligent microprocessor for smarter automation and process control

- Fully isolated standard analogue outputs 4-20mA and 0-10V

- Full digital setup & easy programming

- 10 point linearization, providing superior accuracy

- Increase reliability with 2 single pole relays & digital inputs

- 6 wire load cell connection to compensate for barrier and cable losses

Our intelligent strain gauge bridge amplifier is a compact, stack-able microprocessor based unit specifically designed to control and monitor process applications. Flexible connection to most load cells, pressure or strain gauges over a wide range of sensitivities. The unit provides isolated current 4-20mA and voltage 0-10V analogue outputs and two digital inputs. Two set point relays can be configured to set thresholds such as net, gross, peak and valley. Powered from a wide ranging DC supply, the DIN rail amplifier is supplied with 2 part screw connectors for ease of installation.

Suitable for strain gauges and other ratio-metric sensors and will support 6 wire input to compensate for barrier and cable losses. Factory calibrated to mV/V and supporting 10 point user calibration to desired engineering units. Configuration options via handheld programmer or PC Toolkit software.

The analogue outputs and relays interface to existing acquisition and control systems making this unit an ideal partner for any integrated instrumentation system.

Can be used in conjunction with our LCI load cell failure alarm, which is designed to continuously monitor the condition of individual load cells and activate an alarm when faults in the system are detected, therefore providing increased safety and cost savings onsite for all weighing systems.

Documents

Software

- LC Toolkit : Version 1.8.0 The LC Toolkit software for Windows will allow a connection with the LCA20 via an optional on-board communications module LC4 or via an optional programming cable PGM1.

- Q: Can the LCD20 perform the same functions as the LCA20?

-

A: The LCD20 has most of LCA20's functionality. However, there are a few exceptions. The differences are as follows:

-

The LCD20 does not have an on board display option

-

The LCD20 has two configurable digital inputs

-

The LCD20 is rated as IP20

- The LCD20 runs on a DC power supply

- The LCD20 does not have the on board RS485/RS232 communication outputs (this is the LC4 module on the LCA20)

-

- Q: How do you configure the LCD20?

-

A: This can be done either using the PGM1 cable and Toolkit or the remote handheld programmer (LP2)

- Q: Is the LCD20 toolkit similar to the toolkit used for the LCA20?

-

A: Yes, the navigation of the two is identical and the same user-friendly graphical interface is still in place.

The differences in the two toolkits are only as a result of the difference in the functionality between the products.

- Q: How can I connect to a LCD20 without knowing the baudrate and station number?

-

A: Behind the front panel is a small red button, if you press connect in the LCD Toolkit and press the red button it will auto connect to the module.

- Q: Can the LCD20 provide readings in tension and compression?

-

A: Yes

- Q: Is it possible to connect two LCA20s to one load cell?

-

How would the scaling of each remain stable in the event of a failure of one or the other ?

Can the output of the load cell be connected to both LCAs? With perhaps a resistor network holding the input of the second to a reference ?A: This is done using 6 wire, with the second LCA20 as 5 wire (no "+" excitation).

You could have two 6 wire with two blocking diodes (for redundancy).

Or a separate power supply and two 5 wires. - Q: Can you tell if the calibration has been changed on the LCD20?

-

A: Yes, in the calibration menu you can view the last calibration date and calibration counter.

Required Items and Optional Accessories...

Required Items and Optional Accessories...